The Ultimate Guide to Finding the Best Hydraulic Hose for Sale?

The search for the right hydraulic hose for sale can be daunting. With a growing market predicted to reach $2.3 billion by 2025, understanding your options is crucial. Quality varies widely among manufacturers. A poor choice can compromise efficiency and safety.

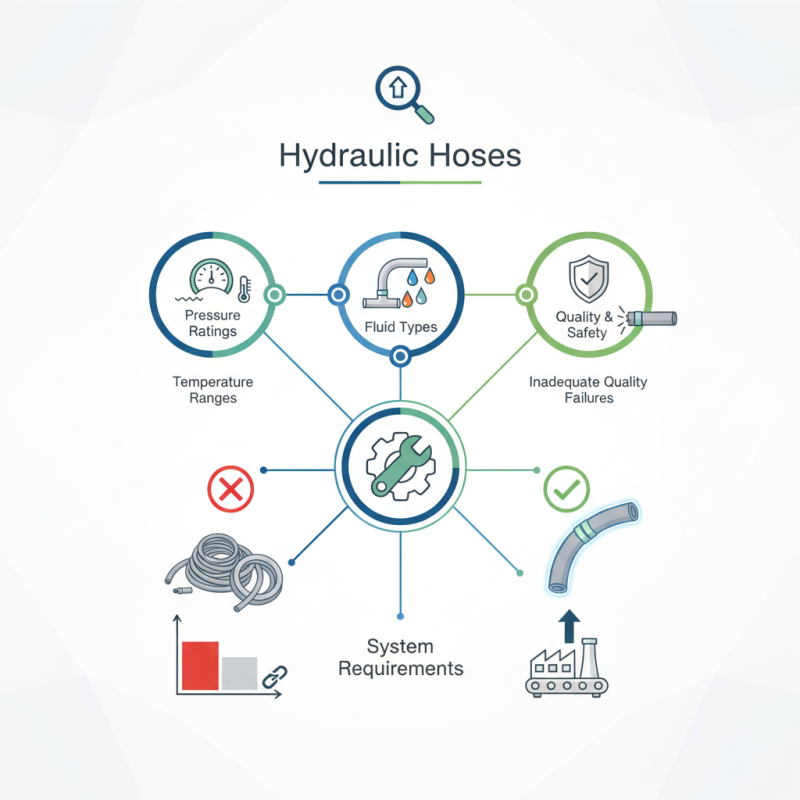

Several factors influence selection. Pressure ratings, temperature ranges, and flexibility all matter. The wrong hose may lead to leaks or failures. Research shows that 30% of hydraulic system failures stem from inadequate hose quality. This statistic emphasizes the need for vigilance. Many users overlook the significance of proper specifications.

However, the available options can be overwhelming. From reinforced hoses to specific types for different fluids, choices abound. It’s easy to make mistakes in this complex field. Prioritize understanding your specific requirements before buying. This ensures the hydraulic hose for sale aligns with your system’s needs. Embrace the challenge and make informed decisions.

Understanding Hydraulic Hoses: Types and Applications

Hydraulic hoses play a critical role in various applications across industries. They are essential for transferring fluid under pressure. Understanding the different types of hydraulic hoses can help users make the right choice.

There are several types of hydraulic hoses. Each has unique properties. For instance, rubber hoses are flexible and resistant to wear. They work well in general hydraulic applications. In contrast, thermoplastic hoses offer a lighter option and are ideal for tight spaces. According to industry reports, the global hydraulic hose market is projected to exceed $3 billion by 2025. This growth highlights the increasing demand for effective hydraulic solutions.

Tips: When selecting a hydraulic hose, consider the environment. Temperature fluctuations can affect hose longevity. Regular inspections can prevent unexpected failures. Additionally, ensure that the hose specifications match your application needs. Using the right hose can boost efficiency and safety in operations.

Another aspect is hose fittings. Proper fittings ensure a secure connection. Undersized fittings can lead to leaks or bursts. Industry experts recommend always double-checking compatibility. A careful approach saves costs in the long run. Remember, addressing these details can make a significant difference in your hydraulic system's performance.

The Ultimate Guide to Finding the Best Hydraulic Hose for Sale

This chart illustrates the different types of hydraulic hoses available and their applications. The data represents the common usage frequency of each type based on industry standards.

Key Factors to Consider When Choosing a Hydraulic Hose

Choosing the right hydraulic hose can be challenging. Many factors affect the performance and longevity of a hose. One major aspect is the application environment. Temperature, pressure, and fluid type all play critical roles. A study by the Hydraulic Institute indicates that over 30% of hose failures result from improper specifications.

Another key factor is the hose material. Different materials can resist various chemicals and abrasions. Polyurethane and rubber are common choices, but they serve different purposes. It’s essential to assess the specific needs based on your operational context. Remember, not all hoses are created equal.

Tip: Always check the hose pressure rating against your system’s pressure. Operating outside this range can lead to premature failure.

Sizing also matters. An oversized hose can reduce system efficiency. Conversely, an undersized option may cause blockages and overheating. Properly sized hoses ensure optimal flow and performance. According to industry reports, nearly 20% of performance issues stem from incorrect hose sizing.

Tip: Measure your existing hoses before purchasing new ones. This ensures compatibility and effectiveness in your application.

Consider each detail when selecting a hydraulic hose. A well-chosen hose can significantly enhance safety and productivity in your operations.

How to Evaluate the Quality of Hydraulic Hoses for Sale

When assessing hydraulic hoses for sale, quality is key. Look for hoses constructed with durable materials. Rubber and synthetic compounds often provide excellent strength and flexibility. Check the hose's pressure rating. A higher rating often indicates a reliable product that can withstand demanding conditions.

Inspect the fittings and connectors as well. They should fit securely and have corrosion resistance. Pay attention to the hose's bend radius. A tighter bend radius can indicate better construction, but may limit the hose's lifespan if stressed. Not all hoses are made the same. Sometimes, you might think a hose looks good, but closer inspection reveals flaws.

Read reviews and seek user feedback. Sometimes, the best information comes from those who have used the product. However, not all reviews are accurate or honest. It’s vital to verify claims and not fall for the hype. Price isn't always a reflection of quality. A cheap hose may save a few dollars but can lead to costly failures. Evaluate all the elements carefully before making a decision.

Where to Find Reliable Suppliers for Hydraulic Hoses

When searching for reliable suppliers for hydraulic hoses, it's crucial to consider specific criteria. Quality of materials is a must. A recent market report indicated that 70% of hose failures are linked to subpar material. This highlights the need for suppliers who prioritize quality in their products.

Location can also affect availability. Suppliers located near major industrial hubs offer advantages. Quick access reduces shipping time and costs. On the flip side, some remote suppliers may provide lower prices but might lack prompt service. Weigh these factors carefully.

Don’t overlook supplier reviews and their reputation. A survey showed that 60% of buyers trust peer reviews more than marketing claims. Seek feedback from other customers. Engaging with seasoned professionals in forums can reveal hidden gems. Remember, the best suppliers may not always be the most apparent choices. Always ask for certifications to ensure compliance with industry standards. Finding the right partner is vital for efficiency and reliability in operations.

Maintenance Tips for Extending the Life of Your Hydraulic Hose

Hydraulic hoses are essential for machinery. Regular maintenance is key to their longevity. Start by inspecting your hoses for signs of wear. Look for cracks or fraying. These small issues can lead to major failures. If you notice anything unusual, replace it immediately.

Cleaning your hoses is also vital. Use a soft cloth to remove dirt and debris. Check the connections for leaks. Even a tiny drip can cause big problems over time. Further, ensure proper storage. Keep hoses in a cool, dry place. Avoid excessive bending or twisting. These habits can shorten their lifespan.

Finally, monitor performance. If your machinery runs differently, check your hoses. Sometimes, we don't notice small changes. Listen for unusual sounds. They might signal trouble. Taking these steps will help maintain your hydraulic hoses. They deserve your attention.