How to choose the right cooling tower for your needs?

Choosing the right cooling tower can be a daunting task. According to industry expert Dr. John Smith, "Selecting the appropriate cooling tower is crucial for operational efficiency." This emphasizes the importance of understanding your specific needs.

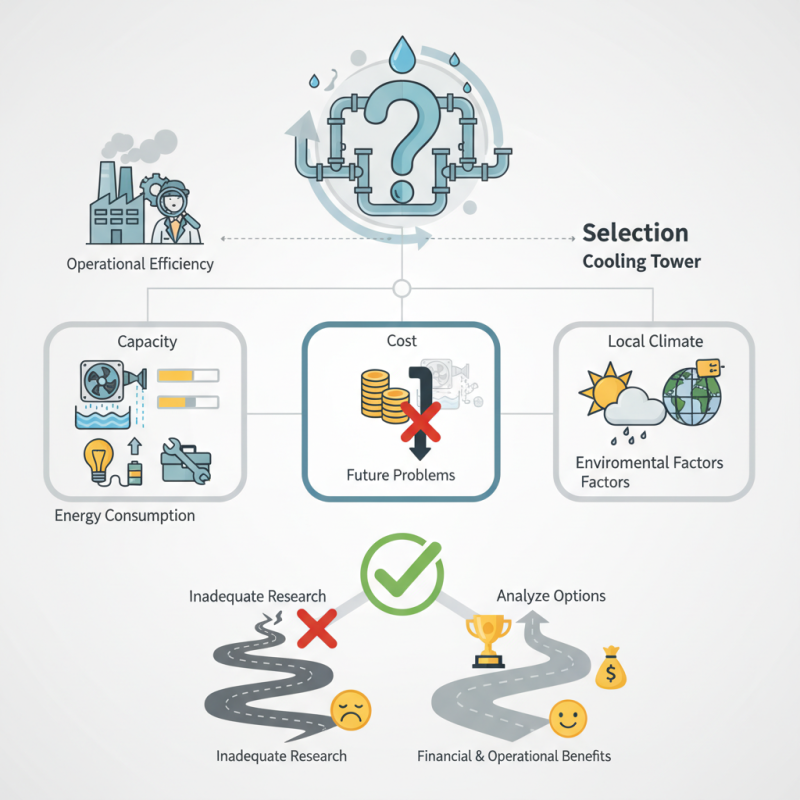

cooling towers come in various sizes and styles. Each type serves different requirements. It’s essential to evaluate factors such as capacity, energy consumption, and maintenance. Many people overlook these details. They might focus solely on cost. However, this can lead to future problems, such as inefficiency or excessive energy usage.

Thinking about your cooling requirements is vital. You must also consider environmental factors. For example, local climate can impact performance. Sometimes, users end up with a cooling tower that does not meet their needs. Inadequate research can have lasting effects, both financially and operationally. Taking the time to analyze the options will pay off in the end.

Identifying Your Cooling Requirements and Specifications

Choosing a cooling tower requires a thorough understanding of your specific needs. Factors like cooling load, water temperature, and environmental conditions play vital roles. According to the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), proper load calculations ensure efficiency. A mismatch could lead to increased operational costs.

The cooling capacity is a crucial metric. It refers to the amount of heat removed per hour. This typically ranges from 10 to 1,000 tons for industrial applications. Selecting a unit too small could result in overheating. Conversely, an oversized tower may lead to wasteful energy use. You might end up spending more. Regular assessments of your cooling requirements are essential.

Consider the location of the cooling tower as well. Proximity to heat sources and prevailing winds can affect performance. The cooling efficiency might be lower if it's poorly sited. Site surveys often highlight these issues. Inadequate positioning could create future problems, underscoring the need for careful planning. Always be prepared to revisit your specifications as operational demands change.

How to choose the right cooling tower for your needs?

| Cooling Requirement | Specification | Recommended Type |

|---|---|---|

| Small Industrial Application | Up to 100 tons, water temperature difference 10°F | Crossflow Cooling Tower |

| Medium Commercial Application | 100-500 tons, water temperature difference 12°F | Counterflow Cooling Tower |

| Large Industrial Application | 500+ tons, water temperature difference 15°F | Modular Cooling Tower |

| High Thermal Efficiency | High heat load with tight temperature control | Hybrid Cooling Tower |

| Space-Constrained Areas | Limited footprint availability | Compact Cooling Tower |

Understanding Different Types of Cooling Towers Available

When choosing a cooling tower, understanding the different types available is essential. There are two main categories: open and closed cooling towers. Open towers use water and air to cool fluids. They are efficient but can lead to evaporation loss. Closed towers, on the other hand, contain water in a closed loop. This minimizes water loss but may require more maintenance.

Before deciding, consider your specific needs. Think about the climate in your area. If humidity is high, an open cooling tower might not be the best choice. Evaluate the physical space you have. Larger towers need more room, but smaller systems may not offer sufficient cooling. It’s a delicate balance.

Tips: Always check energy efficiency ratings. A higher rating often equates to lower operational costs. Don’t forget to ask about maintenance requirements. Some systems may require more upkeep than others. Reflect on your long-term needs. A system that fits today might not work in the future.

Evaluating Energy Efficiency and Environmental Impact

When selecting a cooling tower, energy efficiency and environmental impact are crucial factors. According to the U.S. Department of Energy, cooling towers can account for over 30% of a facility's energy use. Choosing the right model can significantly reduce this consumption. A well-designed tower can enhance energy savings by up to 25% compared to traditional systems. It’s essential to prioritize models that meet the ASHRAE 90.1 efficiency standards.

Examining the environmental impact is equally important. Cooling towers use water, which raises concerns about water scarcity. The Environmental Protection Agency highlights that inefficient towers can contribute to higher water usage. As facilities strive for sustainability, selecting a tower with a low water evaporation rate is vital. This can lead to a reduction in water costs and environmental stress. Not all cooling towers achieve this, and some may fall short of expectations.

Moreover, the choice of cooling tower materials can influence both energy efficiency and environmental impact. For instance, stainless steel offers durability and better resistance to corrosion, which can prolong the system's lifespan. However, the initial investment may be higher. Many facilities lack the necessary analysis to balance cost and benefits, leading to overlooked opportunities for energy savings and sustainability.

Cooling Tower Energy Efficiency and Environmental Impact

Considering Maintenance and Operational Costs

When selecting a cooling tower, maintenance and operational costs are crucial. A well-designed tower minimizes both. Regular maintenance can account for approximately 15-20% of total operational costs. This underlines the value of choosing a reliable system early on. For instance, a tower that requires fewer repairs will save money over its lifespan.

Tip: Schedule regular cleanings. This not only enhances performance but also prolongs the equipment's life.

Operating costs also include energy consumption. Towers with higher efficiency ratings can reduce energy use by up to 30%. An efficient system is not just good for the environment; it lowers your bills. A recent study indicated that facilities that upgraded to high-efficiency cooling towers saw significant savings.

Tip: Monitor energy usage closely. Look for patterns that indicate inefficiencies.

After considering both factors, it's essential to perform a cost-benefit analysis. Some systems look cheaper upfront but may cost more long-term due to maintenance and energy use. Careful evaluation can prevent unexpected financial burdens. Balancing initial investment with ongoing costs ensures better choices.

Assessing Space and Installation Constraints

When choosing a cooling tower, assessing space and installation constraints is crucial. Start by measuring the available area. A compact space requires a different type than a spacious environment. Pay attention to ceiling height and floor space. These factors can limit your options significantly. If the area is too tight, a modular design might be necessary.

Consider the layout of the surrounding equipment. Nearby structures may block airflow. This can affect the cooling efficiency. Ensure there is enough clearance for maintenance. Sometimes, the ideal model just won't fit. This requires a reevaluation of your choices.

Look into local regulations. Certain zones might have restrictions on tower size or type. Ignoring these can lead to complications. It’s essential to balance performance with available space. Spend time visualizing the setup. Can you adjust the environment to accommodate better? Reflect on the practicality of your selection. Each decision shapes performance and efficiency.