How to Choose the Best Butterfly Valves for Sale?

Choosing the right butterfly valves for sale can seem daunting. Industry expert John Marshall once stated, "Selecting the right valve is crucial for optimal performance." His insight emphasizes the need to understand your specific requirements before making a decision.

When searching for butterfly valves, consider their size, material, and compatibility with your system. For example, a stainless steel valve may be preferable in corrosive environments. Proper installation is key. Improper fits can lead to leaks and costly repairs. It’s vital to assess both the initial cost and the long-term reliability of the valve.

Don’t forget to research suppliers and compare offerings. A low price might signal poor quality. This can lead to recurring problems down the line. Think critically about your options. Ensure that the butterfly valves for sale meet your operational needs while being budget-friendly.

Understanding the Basics of Butterfly Valves

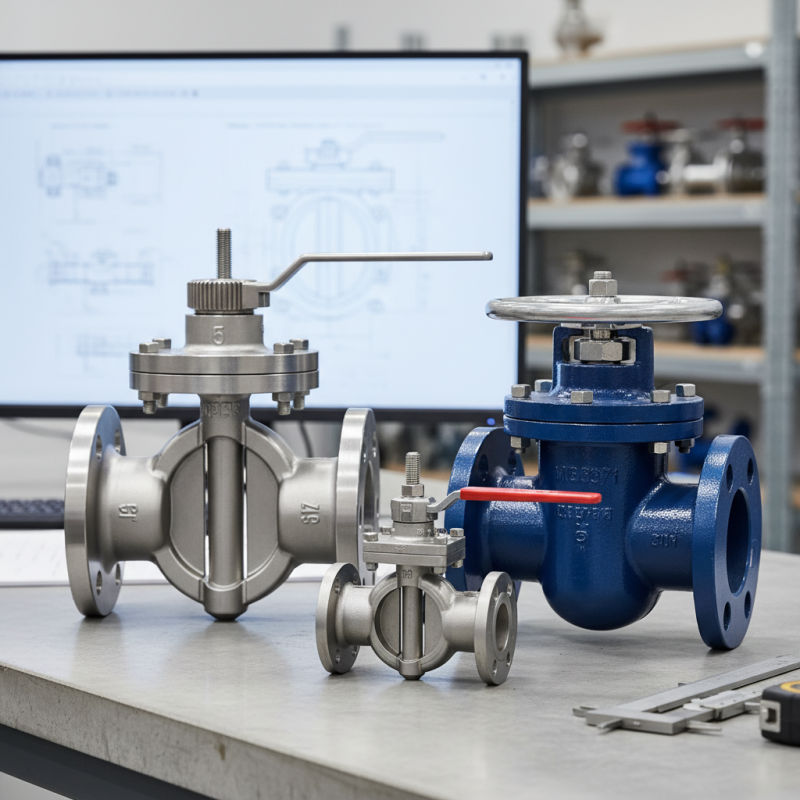

Butterfly valves are essential in various industries for fluid control. Understanding their basic components is crucial. They consist of a disc, a stem, and a seat. The disc is the primary control element that opens or closes the valve. Reports suggest that butterfly valves are often favored due to their lightweight and compact design.

Choosing the right materials is vital for performance. Common materials include cast iron, stainless steel, and PVC. For instance, a recent study found that using stainless steel can enhance resistance to corrosion. This is critical when working with aggressive fluids. While cost may be a factor, longevity should also be considered.

Another important aspect is valve size. It must match your system's requirements. Various sizing charts are available, but they can be misleading. Working with a professional during this phase can prevent costly mistakes. Additionally, consider the valve's pressure rating. Underestimating this could lead to failures. Balancing quality and price is a challenge for many buyers. Thus, thorough research is necessary.

Key Factors to Consider When Choosing Butterfly Valves

When selecting butterfly valves, several key factors must be assessed. The material of the valve plays a crucial role. Common options include stainless steel, cast iron, and PVC. Each material has specific applications and performance characteristics. According to industry reports, stainless steel offers the best resistance to corrosion and high temperatures. However, it tends to be more expensive than other materials.

Another consideration is the valve's size and pressure rating. Choose a valve that fits the system's specifications to ensure proper performance. A mismatch here can lead to failures. Additionally, the design of the valve, such as the disc type, impacts flow characteristics. Research shows that different disc designs can affect turbulence and efficiency.

Tips: Always check for compatibility with your fluid type. This is vital for maintaining system integrity. Also, consider the ease of maintenance. Valves that allow for easy access save time and reduce costs. Remember, a little extra research now can prevent costly repairs later.

Material Options for Butterfly Valves and Their Applications

When choosing the right butterfly valves, material options play a crucial role. Common materials include cast iron, stainless steel, and PVC. Each material has unique properties that influence its performance and suitability for different applications. For instance, stainless steel valves resist corrosion and are ideal for water treatment. However, they can be more expensive than other materials.

Cast iron valves offer durability and strength, making them suitable for high-pressure applications. However, they are heavier and may rust if not properly maintained. PVC, on the other hand, is lightweight and resistant to chemicals, making it popular in the plumbing industry. Yet, it may not withstand high temperatures and pressure as well as metals do.

It’s important to consider the specific environment and fluid type. Some valves perform better in low-pressure systems, while others excel in high-pressure situations. This requires careful evaluation of the needs. Ignoring these aspects can lead to inefficiencies and costly repairs. Finding the right material for your valve is key to achieving optimal performance.

How to Evaluate the Quality and Performance of Butterfly Valves

When evaluating butterfly valves, consider their design and materials. These factors significantly influence their performance and longevity. Look for valves made from durable materials like stainless steel or PVC. They resist corrosion and wear, ensuring they last longer.

Test the seal quality. A good seal prevents leaks. Examine the disc design as well. It should provide a tight closure while maintaining flow efficiency. Additionally, check for certifications. Compliance with industry standards indicates better performance and safety.

Installation and maintenance are crucial. Some valves require specialized tools. This can complicate things. Regular inspection is essential for identifying wear and tear early. A proactive approach can save costs in the long run. Always reflect on your choices. Sometimes, a cheaper option may lead to higher maintenance costs.

Comparing Prices and Brands of Butterfly Valves on the Market

When exploring the market for butterfly valves, it's essential to compare prices and brands effectively. According to recent industry reports, the global butterfly valve market is projected to grow by 5.1% annually, indicating thriving competition. However, not all products deliver equally. Some brands may offer lower prices but compromise on quality, while others may charge more for advanced features.

One crucial aspect of comparing butterfly valves is examining materials. The type of material used can significantly affect price. Premium materials can cost up to 20% more but often provide better durability. Remember, longevity can lead to cost savings in the long run.

Tips: Check for supplier reviews. Understand the warranty offered on products. Research specifications that meet your project needs.

Price isn’t the only factor. Look at designs and functionalities. Some valves are designed with specialized seals. These can increase efficiency but might also increase the initial purchase price. Balancing quality and price is vital.

Tips: Always ask about installation costs. Sometimes, higher-end valves require more complex setups. That could inflate total expenses.